Enhancing Industrial IoT With Robust Edge Computing Diagnostics

Edge computing gateways serve as the pivotal nodes within the Industrial Internet of Things (IIoT) architecture, acting as critical intermediaries between industrial machinery and cloud-based systems. These devices facilitate local data processing and decision-making at the edge, playing a crucial role in the overall efficiency of industrial operations.

However, a significant challenge persists: the effective management and diagnosis of these edge devices in field conditions, particularly when faced with limited resources and harsh environmental factors 1.

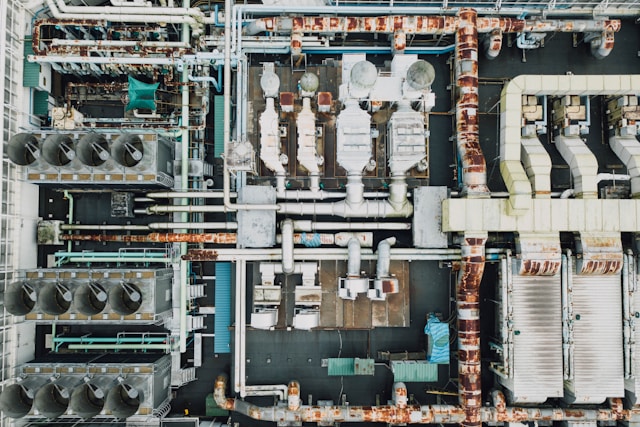

Image by CHUTTERSNAP from unsplash

The Problem: Field Diagnostics for Edge Devices

Field technicians and machine operators frequently encounter difficulties in maintaining and troubleshooting edge devices. Traditional diagnostic methods, such as direct access via a serial console or secure shell (SSH) on a laptop, can be cumbersome and time-intensive. While remote access and fleet management tools offer scalable solutions, their effectiveness diminishes in scenarios where devices lack internet connectivity or face connectivity-related issues 2.

To overcome these challenges, the following strategies can be employed:

- Hybrid Approach: Implement a combined strategy of remote access and local troubleshooting. Remote tools can be utilized for initial diagnostics and configuration, while technicians are equipped with portable devices or tools for on-site interventions.

- Enhanced Connectivity: Investigate alternative connectivity solutions such as cellular modems, satellite links, or mesh networks to maintain reliable communication with edge devices.

- Local Diagnostics Tools: Equip technicians with specialized on-site diagnostic tools or software capable of isolating and addressing issues independently of full internet connectivity.

- Cloud-Based Data Storage: Utilize cloud storage for critical device data and logs, enabling remote access and analysis even under limited connectivity conditions.

- Automated Troubleshooting: Deploy automated scripts or AI-driven tools for identifying and resolving common issues with greater efficiency.

By adopting these strategies, organizations can enhance the efficiency and effectiveness of edge device maintenance and troubleshooting, even in the most challenging environments.

Addressing technical challenges

Field diagnostics for edge devices involve navigating a multitude of technical challenges that can significantly impact the success of diagnostic efforts. Each challenge must be carefully considered when selecting and implementing maintenance strategies.

-

Harsh Industrial Environments: Industrial environments are characterized by extreme conditions such as dust, moisture, temperature fluctuations, and vibrations, all of which can adversely affect the performance of diagnostic tools. Devices operating in these environments must be robust enough to maintain reliable functionality despite these challenges 3.

-

Resource-Constrained Devices: Edge devices often have limited computational resources, including processing power and memory, necessitating the use of lightweight and efficient diagnostic tools. These devices may also rely on constrained power supplies and may lack consistent network connectivity, further complicating diagnostic processes 4.

-

Complex System Interactions: Edge Linux devices require a deep understanding of the Linux operating system, which local operators may not possess. This complexity is increased when diagnostics are performed through interfaces like serial consoles, where specialized knowledge is required 5.

-

Ease of Use in the Field: Technicians require diagnostic tools that are both quick to use and easy to navigate. In field conditions, especially when accessing devices via serial console or SSH, the user interface must be intuitive to minimize the time and effort needed for diagnostics [^11].

Current Approaches and Their Limitations

There are current diagnostic systems that depend on graphical user interfaces (GUIs) or web-based dashboards, which, while effective in controlled environments, pose significant limitations in field applications 6:

-

Resource Intensity: GUIs often require more processing power and memory, which can be a limitation for edge devices.

-

Environmental Sensitivity: GUIs are less practical in harsh field conditions where screen readability can be compromised, and industrial touch screens might not be practical, as it might be too hot or too cold for reliable operation.

-

User Complexity: Navigating through multiple graphical screens can be time-consuming and cumbersome for technicians.

Choosing the Right Interface

The choice of diagnostic interface should be guided by the specific requirements of the application. Text-based interfaces are particularly advantageous in field diagnostics due to their simplicity, resource efficiency, and resilience in harsh conditions. These interfaces are ideal for straightforward processes and serial interactions, enabling experts to conduct diagnostics swiftly and accurately, even with minimal tools 7.

Conversely, GUIs or web-based dashboards may be more appropriate in environments with sufficient processing power, favorable environmental conditions, and a need for complex data visualization.

Ultimately, the interface selection should align with the operational context and the specific requirements of the application, particularly in remote fleet-managed systems 8.

Use Case: Diagnosing Edge Devices in a Remote Industrial Facility

Consider a scenario where a large manufacturing facility operates in a remote, harsh environment, such as a mining site or an offshore oil rig. The facility relies heavily on a network of IIoT edge devices to monitor and control critical operations. These devices must operate reliably despite exposure to dust, moisture, extreme temperatures, and constant vibrations.

In such environments, when an edge device malfunctions or experiences connectivity issues, deploying a technician to diagnose the problem is both costly and time-consuming. The technician must be capable of quickly accessing the device, identifying the issue, and implementing a solution while contending with a lack of local expertise, environmental constraints, and limited device resources.

Choosing the Right Diagnostic Tools

To address these challenges, diagnostic tools must be carefully selected to meet the environmental and operational constraints of the field. Text-based interfaces, for example, are particularly well-suited for these scenarios due to their simplicity, resource efficiency, and resilience in harsh conditions. These interfaces allow for rapid and accurate diagnostics, even with minimal tools and through direct access methods 7.

Examples of Diagnostic Applications

These examples underscore the importance of selecting diagnostic tools and interfaces that are tailored to the specific operational needs and constraints of the application, ensuring that edge devices remain reliable and efficient even in the most demanding industrial environments.

- Software Installer: Specialized installer software can streamline the setup, configuration, and troubleshooting of edge devices in the field. This is particularly valuable in scenarios requiring rapid deployment and reconfiguration, reducing the time and effort needed to maintain operational efficiency.

- Field Diagnostics: Text-based diagnostic tools provide quick assessments and issue resolution for devices operating in remote or harsh environments, where GUI-based tools may be impractical due to resource constraints or environmental conditions.

- Remote Troubleshooting: In cases where remote access is possible but challenging due to connectivity issues, lightweight web-based dashboards can offer a balance between user-friendliness and resource efficiency, enabling technicians to manage multiple devices across a fleet

In conclusion, the field diagnostics of edge devices in industrial environments present unique challenges that require a thoughtful and tailored approach. Effective solutions must be rugged, resource-efficient, and carefully aligned with the specific conditions and requirements of the application. By considering these factors, organizations can enhance the reliability and efficiency of their edge computing infrastructure, ensuring optimal performance in even the most challenging environments.

-

McKinsey, The Internet of Things: Catching Up to an Accelerating Opportunity ↩︎

-

McKinsey, Unlock Value with an Industrial IoT Technology Stack That Scales ↩︎

-

Analog, Intelligent Field Instruments: The Smart Way to Industry 4.0 ↩︎

-

SelectHub, IoT Transforming Field Service Management ↩︎

-

SCAND, Creating a UI for an IoT Application: Things to Consider ↩︎ ↩︎

-

MDPI, The Importance of Diagnostic Tools in Industrial IoT ↩︎