The Importance of Single Board Computers for the Industrial Edge

Introduction and Overview

Industrial IoT (IIoT) is reshaping manufacturing by moving intelligence closer to on-site machinery and sensors. This edge-centric approach helps address challenges such as high latency, network bandwidth constraints, and unplanned downtime—which can exceed $260,000 per hour1. Single Board Computers (SBCs) have become a key element in modern Industrial PCs (IPCs) by offering the reliability and performance needed to reduce downtime and potentially improve ROI12. For further context on the evolution and industrial application of SBCs, overviews are available from LattePanda3 and Maxtang4.

In this article, we explore the role of SBCs at the industrial edge. The discussion covers practical aspects such as cost efficiency, predictive maintenance, and cybersecurity enhancements. By examining how SBC-driven IPCs contribute to resilient and cost-effective manufacturing environments, this article aims to provide valuable insights for those interested in understanding the evolving landscape of Industry 4.0.

Edge Intelligence and Predictive Maintenance

Processing data locally enables predictive maintenance systems to detect anomalies early. For example, an SBC-based system that monitors vibration and temperature can alert engineers to early signs of wear, preventing costly breakdowns56. Additionally, high-performance modules like NVIDIA Jetson extend these capabilities to edge AI tasks—including autonomous robotics and real-time quality inspection—while ensuring data privacy and prompt responses in safety-critical environments789.

Why SBCs Are Integral to Modern IPCs

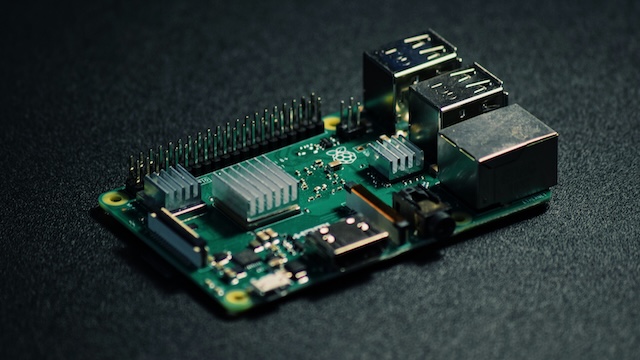

SBC-based hardware integrates processor, memory, storage, and I/O onto a single circuit board, offering several advantages:

-

Lower Costs:

Consolidating components reduces material and assembly expenses, which helps control capital expenditures (CapEx) during large-scale deployments. This streamlined design lowers the total cost of ownership (TCO)42. -

Fewer Moving Parts:

With fanless heat sinks and solid-state storage replacing mechanical components, SBCs minimize hardware failures. -

Reliability in Extreme Conditions:

Industrial SBCs are built to operate in harsh environments with wide temperature ranges and robust enclosures. Secure attachment of components enhances shock and vibration resistance, ensuring dependable performance10. -

Security and Remote Management:

Modern IPCs based on SBCs include features such as secure boot, Trusted Platform Module (TPM) options, and remote firmware updates. These features help safeguard against cyberattacks and simplify maintenance211.

Real-World Impact: Cost Savings and ROI

The benefits of SBC-based IPCs translate directly into financial gains:

-

Reduced CapEx:

The consolidated hardware design means fewer components are needed, lowering upfront costs4. -

Lower OpEx:

Energy-efficient designs, fewer mechanical parts, and remote management contribute to reduced operational expenses2. -

Minimal Downtime:

Effective predictive maintenance combined with robust cybersecurity measures minimizes costly disruptions, protecting revenue streams5612.

As edge computing evolves, the value of SBC-based IPCs will grow, delivering a blend of performance, energy efficiency, and security that drives ROI for manufacturers worldwide.

Addressing Maintainability and Cybersecurity

To fully realize the benefits of SBC-based systems, robust lifecycle management is essential:

-

Regular Updates:

Remotely deploying firmware, OS, and application patches via over-the-air (OTA) updates keeps large fleets secure and operational2. -

Secure Boot and TPM:

These embedded security features verify firmware integrity and prevent unauthorized modifications, forming a critical defense against cyberthreats211. -

Network Segmentation:

Isolating sensitive segments of the production network ensures that any potential compromise remains contained.

These strategies work together to maintain a resilient edge infrastructure and safeguard ROI.

Conclusion

Single Board Computers have become foundational to modern Industrial PCs by merging compact hardware design with industrial-grade reliability, security, and manageability. Embracing SBC-based architectures at the edge allows organizations to reduce costs, streamline maintenance, and fortify operations against disruptions. Supported by industry insights138, this robust integration underscores why SBC-driven IPCs are central to the evolution of Industry 4.0.